For three generations, Dunstans has been delivering ground breaking

projects all across the country.

As remote area specialists, our knowledge of Australia’s geography and geology enables us to work closely with our clients in finding strategic, timely solutions to complex and large-scale challenges.

FILTER CASE STUDIES

- All

- Oil & Gas

- Rail

- Trenchless

- Utilities

Macquarie River HDD

Client Dubbo Regional Council

Description Installation of a new potable water pipeline using HDD under the Macquarie River

Project date April 2018 – July 2018

Project location Dubbo, New South Wales

Pipe type 400mm HDPE PN20

Crossing length 300m

Logan River HDD Crossing

Client Diona Pty Ltd / Energex Limited

Description Installation of a bundle of five conduits under two sections of the Logan River in QLD

Project date July 2016 – September 2016

Project location Logan Reserve, Brisbane

Pipe type Bundle of: 3 x 250mm HDPE PN20 2 x 140mm HDPE PN20

Crossing length 810m

VNIE – Goulburn River Crossing

Client Spiecapag Lucas / APA VTS Australia Pty. Ltd.

Description Installation of a new 400mm Steel Pipeline, duplicating sections of the existing line.

Project date June 2016 – August 2016

Project location Seymour, Victoria

Pipe type 400mm Powercrete Coated Steel

Crossing length 630m

Orford Sewer Outfall Project

Client Jemrok/TasWater

Description Installation of a 225mm HDPE pipe to serve as an outfall for the Quarry Point Water Reclamation Plant

Project date May-June 2016

Project location Orford, Tasmania

Pipe type 225mm SDR 9 HDPE

Crossing length 500m

LCRP Bentleigh Dewatering

Client John Holland Group / LCRP

Description Installation of four horizontal dewatering pipelines to lower the water table for the LCRP

Project date March 2016 – May 2016

Project location Bentleigh, Melbourne

Pipe type Drilled 160mm HDPE PN16 installed within filtering membrane inside 250mm HDPE PN20

Crossing length 2 x 700m 2 x 650m

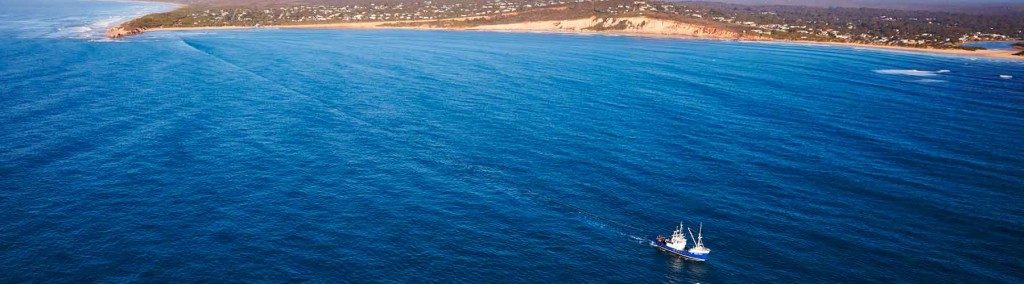

Anglesea WRP Outfall Replacement

Client Barwon Water

Description Installation of a 355mm HDPE outfall and 18m steel diffuser to replace damaged outfall pipe

Project date September 2015 – December 2015

Project location Anglesea, Victoria

Pipe type 355mm SDR 9 HDPE

Crossing length 700m

Yorke Peninsula FOC

Client South Australian Power Networks

Description Installation of 100km of 35mm Emtelle Microduct

Project date January 2015 – May 2015

Project location Yorke Peninsula, SA

Pipe type 35mm HDPE

Fibre length 100km

WIF Interconnect Pipeline

Client Transfield Services Australia

Description Installaton of 600mm OD gas pipeline as part of QGC’s WIF Pipeline Project

Project date January – February 2014

Project location Wandoan, Queensland

Pipe type 600mm OD Carbon steel gas pipe

Pipe length 1,600m

Anglesea River HDD Crossing

Client Barwon Water Alliance

Description Installation of 340m of 315mm HDPE rising main under the Anglesea River by HDD

Project date November – December 2011

Project location Anglesea, Victoria

Pipe type 315mm OD HDPE pipe

Crossing length 340m

VicTrack Fast Rail Project

Client Visionstream

Description To install 42km of FOC conduit from Clarkfield to Sydenham

Project date 2005

Project location Victoria

Pipe type 63mm HDPE pipe

Crossing length 42km

Telfer FOC Install

Client Silcar Communications Pty Ltd

Description Fibre Optic Cable Installation from Telfer mine to the Pardoo Roadhouse

Project date August 2006 – November 2008

Project location Western Australia

Fibre type 24 fibre

Fibre length 350km

Senex Composite Pipeline

Client Senex Pty Ltd

Description Installation of 10km of spoolable composite pipe by plough methodology and associated infrastructure

Project date August 2014

Project location Cooper Basin, SA

Pipe type 4’’ Fibrespar Composite Pipe

Fibre length 10km

QCLNG Trunk Lines Project

Client QGC (a subsidiary of BG Group)

Description Installation of underground 33 kV HV and FOC cables to supply field compressor stations for regional storage pumping stations

Project date March 2013 – Ongoing

Project location Queensland

Cable type 33 kV HV and FOC

Cable length 100km

QCLNG MCJV FOC Install

Client MCJV (MacDow and CCC Joint Venture) for QGC

Description Installation of a 540km network of FOC and associated infrastructure

Project date November 2011 – October 2013

Project location Queensland

Fibre type 6 core, 48 fibre armoured cable

Fibre length 540 km

Pingrup FOC Install

Client Silcar Communications Pty Ltd

Description Fibre Optic Cable Installation to the Pingrup area

Project date June 2006 – July 2006

Project location Pingrup, South Australia

Fibre type 24 fibre

Fibre length 35km

Node 4 HDD Conveyor Crossing

Client Bundaberg Regional Council

Description Installation of a 10-inch gas pipeline under the Carborough Downs Conveyor by HDD

Project date November 2013

Project location Queensland

Pipe type 10-inch carbon steel pipe (Grade B API 5L)

Crossing length 140m

Mitcham Stormwater HDD Outfall

Client John Holland Group

Description Installation approximately 100m of 500mm HDPE pipe by HDD

Project date March – April 2014

Project location Melbourne, Victoria

Pipe type 500mm OD HDPE SDR11 pipe

Crossing length 100m

Marble Bar FOC Install

Client Silcar Communications Pty Ltd

Description Fibre Optic Cable Installation to Marble Bar township

Project date December 2006 – February 2007

Project location Pilbrara Region, Western Australia

Fibre type 24 fibre

Fibre length 180km

Macedon Pipeline Project

Client Streicher Clough Joint Venture for BHP Billiton

Description FOC installation as part of the Macedon liquefied natural gas project

Project date 2011

Project location Western Australia

Fibre type 48 single core

Fibre length 70km

King Lake FOC Install

Client Silcar Communications Pty Ltd

Description Fibre Optic Cable Installation from Hyden to Lake King

Project date July 2006 – November 2008

Project location Western Australia

Fibre type 24 fibre

Fibre length 150km

Karara Mine Site FOC Install

Client Silcar Communications Pty Ltd

Description Install 15km of dual FOC cable

Project date 2010

Project location Karara Mine Site, Western Australia

Fibre type 48 core FOC

Fibre length 15km dual

Isaac River HDD Crossing – Moranbah

Client AJ Lucas / Arrow Energy

Description Design, construct and install a 300mm gas pipeline under the Isaac River by HDD

Project date September 2013 – October 2013

Project location Moranbah, Queensland

Pipe type 12 inch carbon steel pipe (Grade B API 5L)

Crossing length 550m

Horizontal Extraction Well

Client Senversa

Description Horizontal Dewatering Well Installation

Project date June – July 2014

Project location Melbourne, Victoria

Hole length 385m

Francis FOC Install

Client Silcar Communications Pty Ltd

Description Fibre Optic Cable installation within Francis township

Project date June 2006

Project location South Australia

Fibre type 24 fibre

Fibre length 32km

Colac Pipeline – Olangolah Weir HDD Crossing

Client Barwon Water Alliance

Description Installation of 500mm HDPE pipe by HDD

Project date May – October 2011

Project location Olangolah Weir, Otway Ranges, Victoria

Pipe type 500mm OD HDPE pipe

Crossing length 292m

Colac Pipeline – Eel Creek HDD Crossing

Client Barwon Water Alliance

Description Installation of 500mm HDPE pipe in the Otways by HDD

Project date May – October 2011

Project location Eel Creek, Otways Ranges, Victoria

Pipe type 500mm OD HDPE pipe

Crossing length 330m

Caltex Jet Fuel Pipeline

Client Caltex Refineries (QLD) Pty Ltd

Description Installation of new 250mm poly -coated steel jet fuel pipeline and a replacement section of 200mm poly-coated steel fuel line

Project date September 2014 – February 2015

Project location Lytton and Pinkenba, Brisbane

Pipe type 250mm Poly Coated steel 200mm Poly Coated Steel

Crossing lengths 2 x 540m 1 x 270m 1 x 1100m

Burnett River HDD Crossing

Client Bundaberg Regional Council

Description Installation of 360m of 450mm HDPE sewer pressure main by HDD

Project date June 2013 – August 2013

Project location Queensland

Pipe type 450mm OD HDPE pipe

Crossing length 360m

BHP RGP5 Rail Duplication

Client Visionstream – BHP Billiton

Description Dual FOC installation as part of BHP Billiton RGP5 Project

Project date August 2009 – March 2010

Project location Pilbara, WA

Fibre type 48 core

Crossing length 250km dual core